- Welcome to Anping County HengYa Hardware Wire Mesh Co.,Ltd.

Products

- Stainless Steel Woven Wire Cloth

- Stainless Steel Rope Mesh

- Basket Filter

- Knitted Mesh

- Shale Shaker Screens

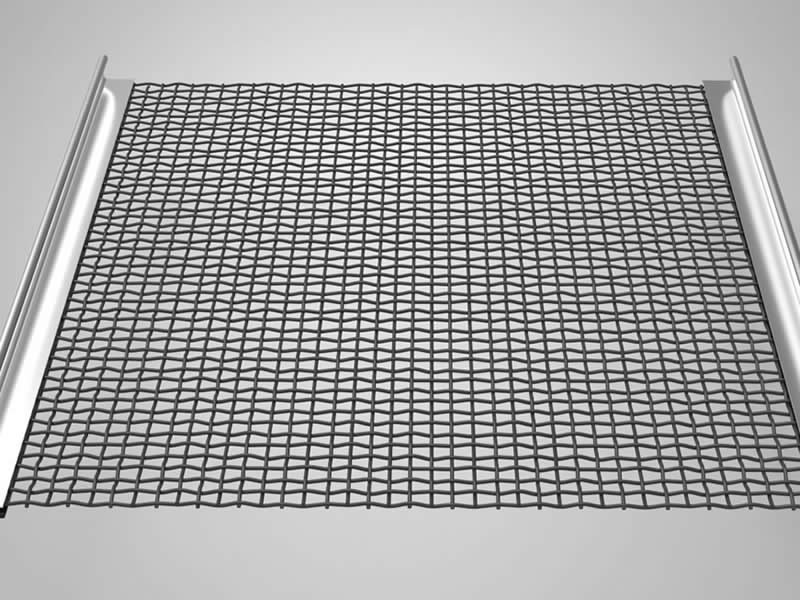

- Vibrating Screens

- Wedge Wire Screen

- High Tensile Wire Screens

- Filter Elements

- Filter Cylinders

- Test Sieve

- Filter Discs

- Brewery Filter Screens

- Temporary Basket Strainer

- Pipeline Temporary Strainers

- Plate Perforated Strainers

- Standard Gasket

- Sock Screen Gasket

- Orifice Plates Gasket

- Demister Pad

Products

Home > Products > Vibrating Screens

Connect With Us

- sales1@filterscreenchina.com

- sales2@filterscreenchina.com

- TEL: +86-318-7662066 7750536

- FAX: +86-318-7750537